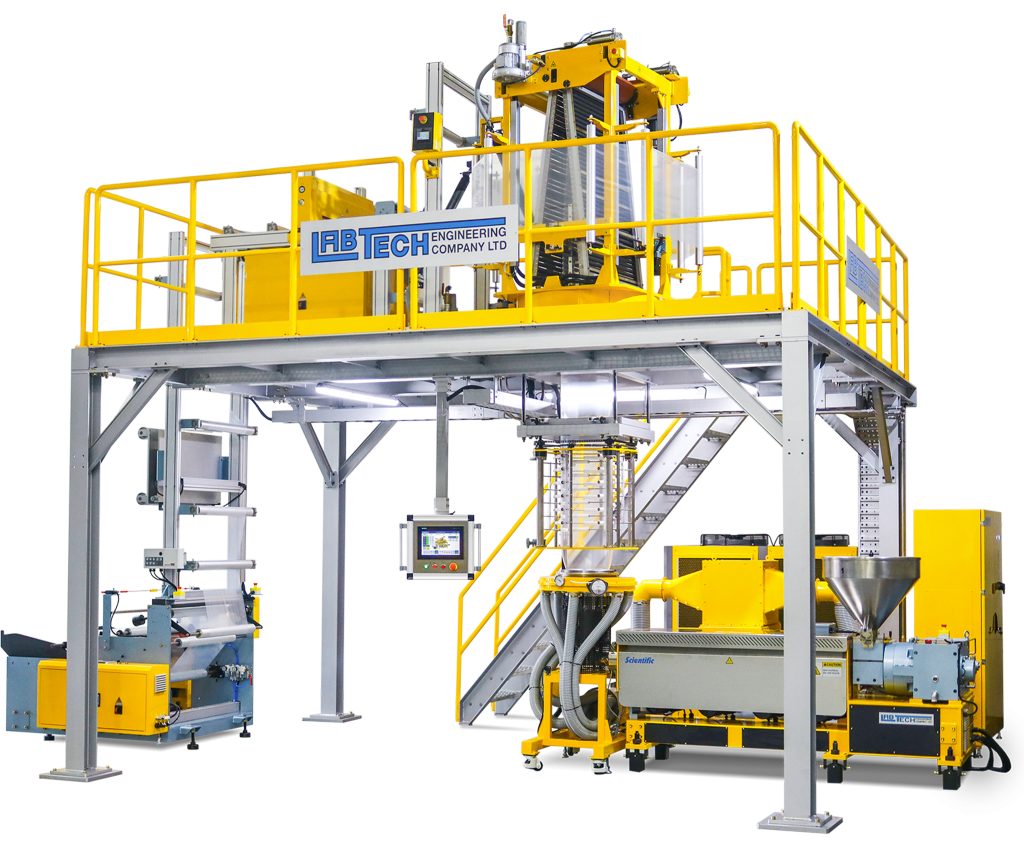

Společnost Labtech Engineering byla založena v Thajsku před 35 lety a dnes je jedním z největších výrobců strojů na zpracování polymerů v laboratořích a poloprovozních závodech na světě. Naše stroje vyrábíme pod švédským vedením a technologií s vysoce oddaným thajským týmem inženýrů a techniků. Před několika lety jsme se přestěhovali do naší ultramoderní továrny.

![]() Meet the NEW Filter Tester Mark II – Type LFTX34-GP / MARK II

Meet the NEW Filter Tester Mark II – Type LFTX34-GP / MARK II

![]() Labtech has decades of experience in filter tester development, and the quality and performance of the standard compact filter tester developed by Labtech have been widely proven by customers over many years.

Labtech has decades of experience in filter tester development, and the quality and performance of the standard compact filter tester developed by Labtech have been widely proven by customers over many years.

![]() Today, our objective is to extend this proven testing solution to more customers. The Filter Tester Mark II (LFTX-34/MARK II) has therefore been introduced as the direct successor to the standard Compact Filter Tester (LCFT34-GP), maintaining the exact same reliable testing performance while offering a much more affordable investment level.

Today, our objective is to extend this proven testing solution to more customers. The Filter Tester Mark II (LFTX-34/MARK II) has therefore been introduced as the direct successor to the standard Compact Filter Tester (LCFT34-GP), maintaining the exact same reliable testing performance while offering a much more affordable investment level.

![]() Beyond cost optimization, the LFTX-34/MARK II line also introduces additional user-friendly features and a significantly shorter delivery time. The result is not only a more accessible filter tester, but a more complete and practical solution, delivering added value without changing the performance laboratories rely on.

Beyond cost optimization, the LFTX-34/MARK II line also introduces additional user-friendly features and a significantly shorter delivery time. The result is not only a more accessible filter tester, but a more complete and practical solution, delivering added value without changing the performance laboratories rely on.

Highlight Features

⭐ Smarter design. Faster workflow. Same trusted results.

⭐ Built to make high-quality filter testing more accessible than ever

⭐ 2-month delivery time for faster laboratory readiness

⭐ LT FlashPak Filter Device for fast, precise, and repeatable filter loading

⭐ Affordable investment level with proven testing performance

⭐ Flexible data access via touchscreen control or external display

⭐ Refined compact design with aluminum profile construction

⭐ All-in-one configuration simplifying daily operation

Interested in the latest evolution in laboratory filter testing?

![]() Contact us: labtech@labtechengineering.com

Contact us: labtech@labtechengineering.com

![]() Connect with Labtech Engineering to explore our full range of laboratory and R&D solutions.

Connect with Labtech Engineering to explore our full range of laboratory and R&D solutions.

#LabtechEngineering #FilterTester #PolymerTesting #LaboratoryInnovation #PlasticIndustry #QualityControl #EngineeringExcellence

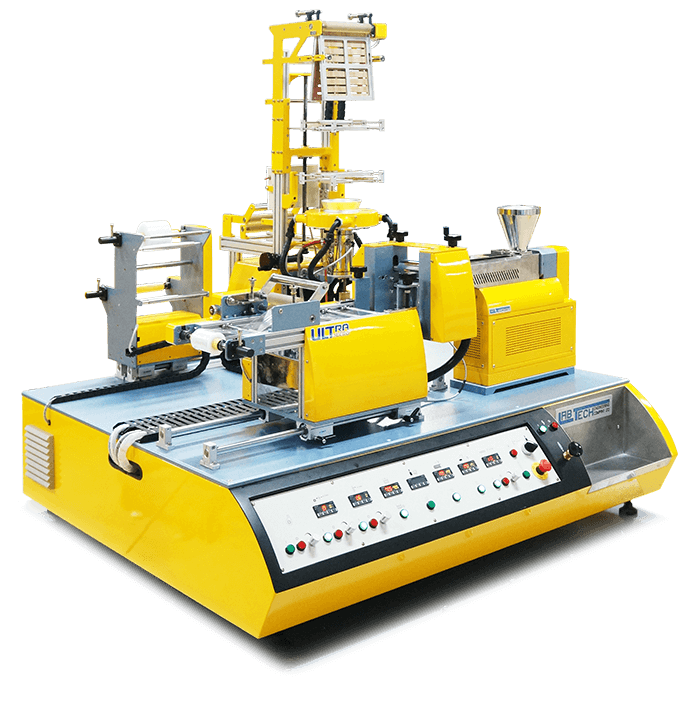

Discover Labtech’s New Mini Scientific Combi Line – One Platform, Two Capabilities

The Mini Scientific Combi Pelletizing & 3D Filament Extrusion Line is a compact, dual-purpose solution designed for R&D labs, universities, and small-batch production. It combines 3D filament extrusion and strand pelletizing on a single, space-saving platform, delivering precision, flexibility, and efficiency at laboratory scale.

Producing 1.75 mm 3D filament or uniform pellets, with water or air cooling options, the system adapts easily to a wide range of polymers and research needs.

▶️ Watch the video to see the line in operation

📖 Read our newsletter for this line via the link for full technical details

#LabtechEngineering #3DFilament #Pelletizing #R&D #PolymerProcessing #LaboratoryEquipment #MiniScientificLine

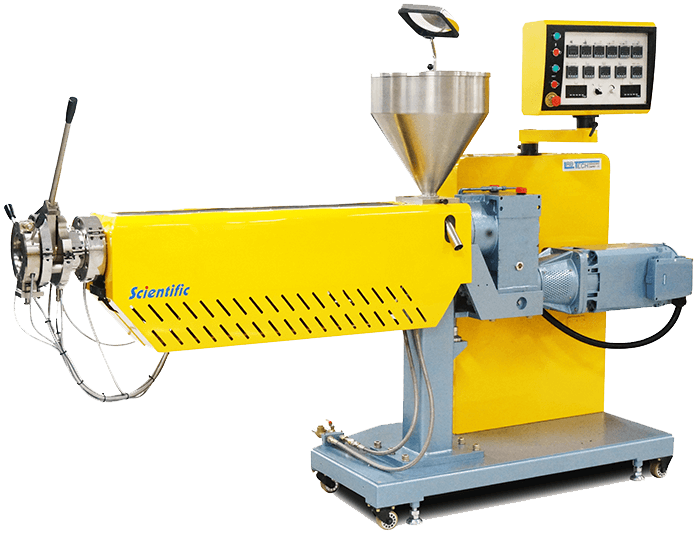

Medical-grade polymers are highly sensitive to temperature variation. In conventional single-screw extrusion, inconsistent thermal control often leads to gel formation and surface defects, making stable film production difficult. To solve this, Labtech Engineering developed a dedicated single-screw extruder paired with a cast film unit, specifically engineered for medical polymers. The result is highly consistent temperature control, gentle melt handling, and significantly reduced gel formation.

Key Features:

✅ Wide chill-roll temperature range (10–120 °C) with a precision two-roll chill-roll system

✅ Exceptionally stable thermal control from extrusion to winding

✅ Low-shear extrusion design for uniform, gel-free films

✅ GMP-compliant construction for medical and pharmaceutical applications

Discover the full solution and performance results in our latest Newsletter 📰 and watch the video 🎥 to see the LCRM/2/145-300 Cast Film Extrusion Line in action.

Labtech Engineering proudly introduces the new TILTEX Cast Film/Sheet Co-Extrusion Line, with motor-driven die lip adjustment, MCAD thickness control, and integrated film spot reader, designed for research centers and pilot plants that demand maximum precision, consistency, and quality control.

🎯 Key Innovations:

• Automatic Flat Die with MCAD Thickness Gauging System and In-line Scanner — delivers precise, micro-step die lip adjustment with real-time thickness monitoring and automatic correction for consistent, high-quality film production.

• TILTEX Multi-Angle Chill Roll Stack — operates in vertical, horizontal, or inclined positions for unmatched flexibility

• Integrated Film Spot Reader — real-time detection of gels, pigment clusters, and defects

💡 Applications:

Ideal for developing high-quality films and sheets using polyolefins (PE, PP), polyamides, PET, biodegradable polymers (PLA, PBAT, PHAs), and numerous specialty blends.

Experience the next level of precision polymer processing — where automation meets innovation.

🔗 Download our Newsletter to learn more!

#LabtechEngineering #PolymerProcessing #CastFilmLine #FilmExtrusion #SheetExtrusion #CoExtrusion #ExtrusionTechnology #LaboratoryLine #PilotLine #RDCenter #PolymerInnovation #AutomaticFlatDie #MCADControl #FilmSpotReader #ThicknessControl #InlineScanner #AutoAdjustingDie #ChillRollStack #PrecisionExtrusion #SmartExtrusion #QualityMonitoring

Bangpoo Industrial Estate, 818 Moo 4, Soi 14B Sukhumvit Road, Praksa, Muang, Samutprakarn 10280, Thailand

Tel.: 66-2-709 6959

© 2023 Labtech Engineering. All rights reserved. Web design and development by Orangetech.